Description

Key Features:

- Material: The blades are crafted from precision-hardened Chrome-Vanadium-Molybdenum steel, providing durability and resistance to wear and tear.

- Design: Featuring an ergonomic, soft-grip, multi-component handle for comfort and effective torque transmission. The blade insulation is directly moulded onto the blade, ensuring comprehensive protection.

- Insulation: Utilises orange insulation achieved through a unique injection moulded process, covering the entire screwdriver for maximum safety.

- Compliance: All screwdrivers are insulated according to IEC 60900 standards, making them suitable for use up to 1000 V AC/1500 V DC.

- Identification: Permanent laser marking on each screwdriver prevents fading, ensuring visibility and traceability over time. Additionally, each product is assigned a batch number for easy traceability.

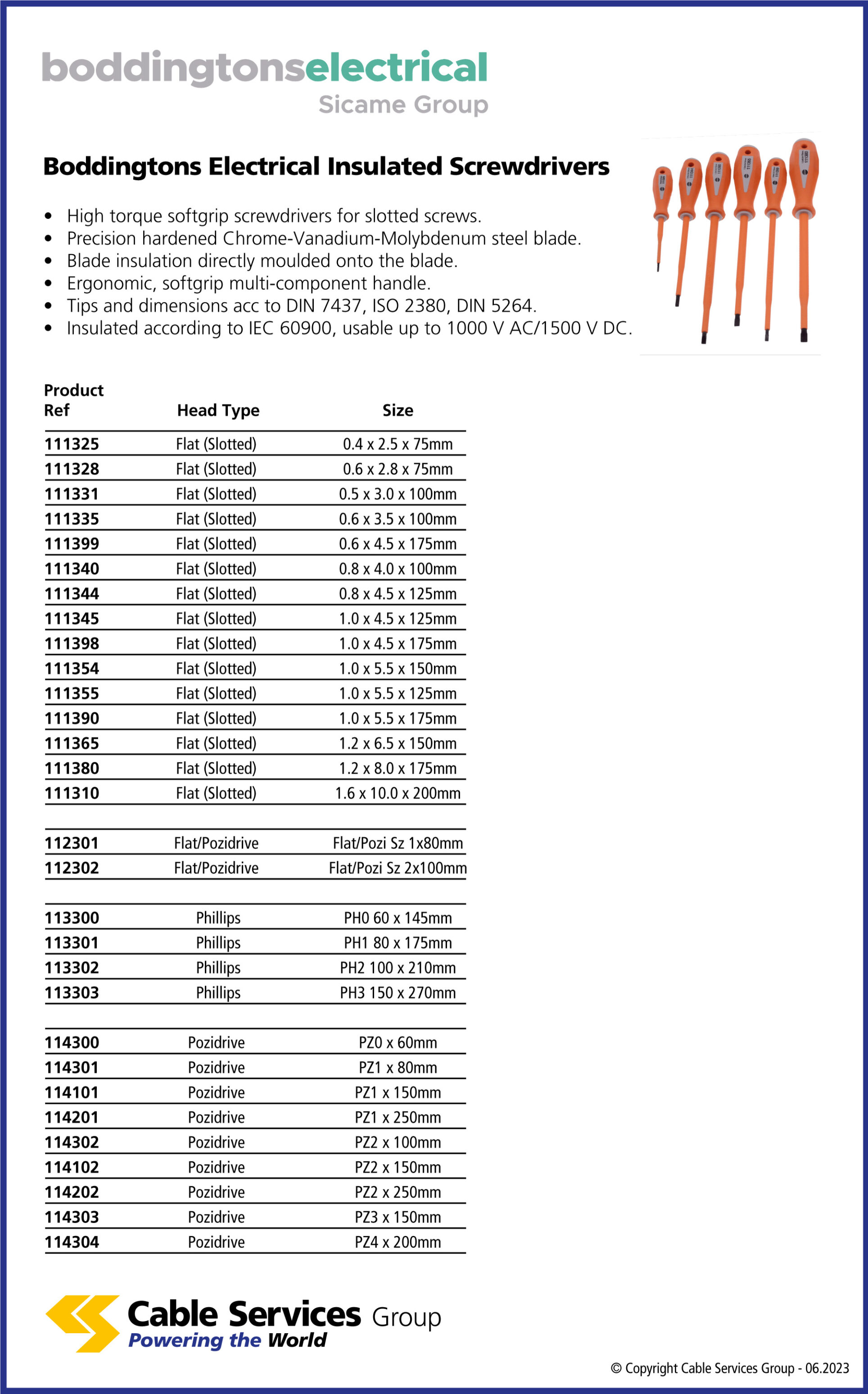

Available Types and Sizes:

The screwdrivers come in various types and sizes, including flat/slotted, Phillips, and Pozidrive, catering to different requirements. Sizes range widely, ensuring suitability for a broad spectrum of applications, from precise electronic work to more demanding electrical installations.

Applications:

Designed for professional use, these screwdrivers are ideal for a variety of electrical tasks, including installation, maintenance, and repair of electrical components and systems in residential, commercial, and industrial settings.

Benefits:

- Safety: Provides significant protection against electrical shocks, enhancing safety during electrical work.

- Durability: The use of high-quality materials and construction techniques ensures longevity and reliability.

- Versatility: A wide selection of sizes and types allows for flexibility across different tasks and applications.

- Compliance: Meets international safety standards, ensuring the tools are safe for professional electrical work.

Considerations:

When selecting an insulated screwdriver, it’s important to choose the correct type and size for the task at hand. Consider the voltage rating and ensure it matches the requirements of the electrical systems you’re working on. Regular inspection and maintenance of the tool are recommended to maintain its safety and functionality.